Tempered glass is now everywhere in modern buildings. From skyscraper façades to residential balconies, you see it in projects where strength, safety, and visual clarity are non negotiable. But there’s one factor that doesn’t always get talked about enough, flatness. When a sheet of glass isn’t flat, you notice distortion, reflections bend in strange ways, and entire designs can lose their intended look. For architects, builders, and end users, this detail can make or break the value of a project.

Landson Glass has become a trusted supplier in Australia, New Zealand, and Europe because of its focus on delivering very flat, high quality tempered safety glass. The company meets strict international standards and provides tailored solutions with heat treated glass in oversized, curved, or processed formats. With in house equipment for polishing, drilling, CNC shaping, and even waterjet cutting, it handles complex requirements without passing work down the chain. Lead times stay reasonable at two to three weeks ex factory, and timber end caps or custom crates are available for safe delivery. If you need more than just standard tempered glass, Landson Glass shows how professional processing and consistency protect your investment and your reputation.

Why Does Flatness in Tempered Glass Matter?

Flatness matters because light travels straight. Any small wave or bend in glass changes the way reflections appear. This is not just an aesthetic concern, it influences safety and usability too. If you’re installing glass in a façade, distortion can alter the appearance of a building. For interior partitions, it can make objects look out of alignment. Even in something as common as a shopfront, a wavy reflection can affect the customer’s experience.

What Problems Can Poor Flatness Create?

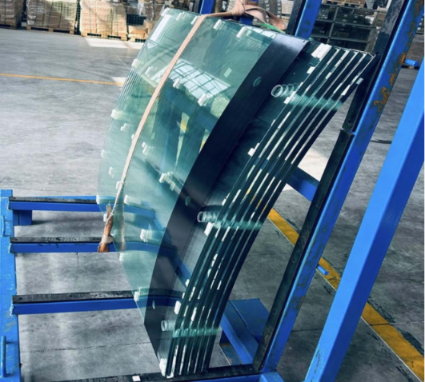

When tempered glass comes out of production with uneven surfaces, you often see roller wave distortion. This is caused by the glass sagging slightly while it’s on rollers during heating. If not controlled, the surface won’t look smooth and reflections bend unnaturally. In some cases, poor flatness also affects installation, especially in large panels up to 2700 x 5000 mm where even a slight wave is amplified. Architects and contractors spend money and time making a space look perfect, so it’s frustrating to have the glass undo all that work.

How Is Flatness Controlled in Tempered Glass?

Flatness starts with the right process. Toughened glass is made by heating standard glass to a high temperature and cooling it rapidly. The key is keeping that cycle stable so the surface doesn’t bend or twist.

What Role Does Equipment Play?

Advanced tempering furnaces and handling systems make a huge difference. Controlled heating zones and accurate roller systems reduce roller wave. If you’re sourcing glass, always ask about the equipment being used. Companies that invest in CNC processing, waterjet machines, and shaped edge equipment usually also maintain their tempering furnaces at high standards. This combination results in flatter surfaces, better cutouts, and precise corners.

How Do Thickness and Size Affect Flatness?

The thicker the glass, the harder it is to maintain absolute flatness. Glass up to 19 mm can be tempered, but keeping a large 5000 mm panel both strong and flat requires careful balancing. Thin panels may distort more easily during heating, while thicker sheets resist bending but demand higher control over heat distribution. This is why sourcing from a supplier that regularly handles oversized sheets is safer.

What Options Protect Flatness and Safety?

Besides the standard tempering process, you might need extra steps depending on the project. Flatness isn’t only about looks, it ties directly to safety.

When Should Heat Soaking Be Considered?

Heat soaking is a process where tempered glass is reheated and held at a steady temperature to release potential nickel sulfide inclusions. These inclusions are a hidden risk and can cause spontaneous breakage. Heat soaking helps screen out defective panes. For large façades or glass above pedestrian areas, this added step is a strong insurance policy.

What About Heat Strengthened Glass?

Sometimes you don’t need the full stress of tempered glass, but you do need better performance than annealed glass. Heat strengthened glass offers that balance. It’s less likely to distort than fully toughened panels and often used when flatness is critical but impact strength requirements are lower.

Where Does Customized Processing Fit In?

Flat glass is rarely left plain. Most projects require drilling, cutouts, edge finishing, or even shaping. The flatter the base glass, the better those processes look and perform.

How Do Complex Shapes Affect Flatness?

When glass has holes or cutouts, the stress distribution changes. This can amplify any existing distortion if not handled carefully. With modern CNC and waterjet machines, complex shapes can be achieved without compromising surface quality. For example, tempered glass with complex shapes can be drilled, polished, or even curved while still meeting flatness requirements. This opens doors for architects who want creativity without giving up safety.

Why Do Edge Finishes Matter?

Edges may look like small details, but they play a part in stress balance. Poorly polished edges can start cracks. Rounded or shaped edges not only improve safety but also reduce the risk of stress points that would distort flatness over time.

How Do You Source the Right Flat Tempered Glass?

If you’re choosing tempered glass for a project, flatness should be on your checklist along with safety, strength, and size. Ask about processing capability: up to 19 mm toughened and 12 mm heat strengthened covers most architectural needs. Confirm maximum size limits, 2700 x 5000 mm works for curtain walls and large atriums.

Equally important is how quickly you can get it. Lead times of two to three weeks ex factory are realistic for large runs. Proper packaging with timber caps or crates ensures the flatness achieved in the factory isn’t lost during shipping. Visiting a supplier’s gallery can also give you real world evidence of flat installations that maintain clarity and line accuracy. For reference, you can check project samples here.

Finally, keep communication open. A good supplier will provide drawings, processing options, and guidance on whether heat soaking or heat strengthening is needed. If you’re in doubt, don’t hesitate to reach out directly and get tailored advice before committing to an order.

FAQ

Q1: What makes tempered glass flatter than regular glass?

A: The controlled heating and cooling cycle plus precision rollers in modern furnaces reduce natural sag, keeping surfaces smoother than untreated glass.

Q2: Why does roller wave distortion happen?

A: It occurs when glass softens and sags slightly between rollers in the furnace. Poor control over temperature and roller speed usually makes it worse.

Q3: Is heat soaked glass always necessary?

A: Not in every case, but it is strongly recommended for high rise façades, skylights, or panels installed above people, where breakage risk carries higher consequences.

Q4: Can curved tempered glass still meet flatness requirements?

A: Yes. Curved panels are produced with specialized shaping equipment. When processed properly, they remain smooth without uneven distortions.

Q5: What should you look for when choosing a supplier?

A: Check for compliance with standards, maximum size capability, processing options like CNC and waterjet cutting, heat soaking availability, and consistent lead times.