Why Multi-Laminated Glass Panels Matter

In today’s building world, glass is not only a clear wall. You find it forming fronts, outlining steps, and making open rooms. But the more you use glass, the tougher and safer it has to be. One plain laminated sheet could work for regular doors or windows. However, when it comes to guard rails, handrails, or big sheets, multi-laminated glass panels come into play. They provide extra layers, added power, and greater toughness. This makes them perfect for tricky building jobs.

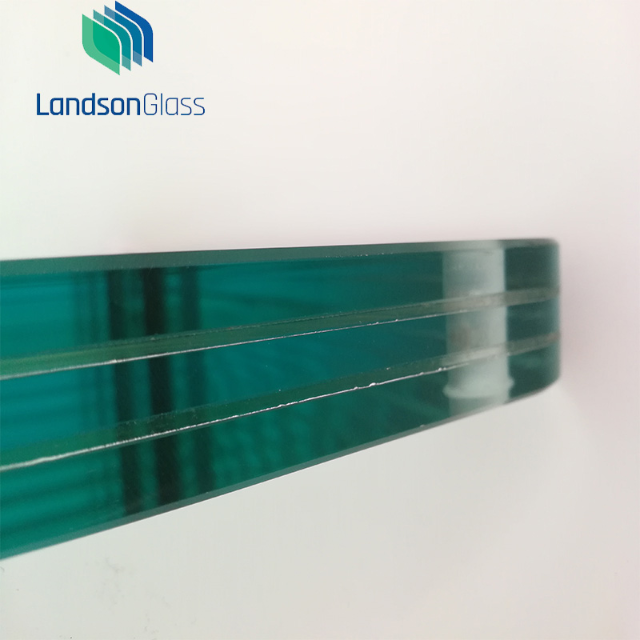

Laminated glass is made with two or more sheets stuck by a middle layer. That middle layer keeps bits together if it breaks. So, it cuts down harm from pointy bits. When you stack many laminates, the work shifts a lot. You gain hit resistance, improved sound blocking, and a safety edge that single sheets can’t give.

What Laminated Glass Is and How Multi-Laminated Differs

Standard Laminated Glass Basics

Laminated glass gets made by joining glass sheets with stuff like PVB, SG®, or Vanceva®. These middle layers form a lasting sandwich that fights coming apart. Even if the glass breaks, the middle layer holds it whole. This is why laminated glass shows up a lot in safety guards, shower walls, or business spots.

Multi-Laminated Glass Explained

Multi-laminated panels just add more layers. For instance, a panel might mix three or four sheets instead of two. It has several middle layers between them. Thickness can go from 9.52 mm up to 33.04 mm. These choices let you fit the building needs of step handrails, wall curtains, or even bullet proof glass. The more layers you add, the harder the glass acts under pressure.

Where Multi-Laminated Panels Are Used

Balustrades and Stair Railings

One of the top uses is in balustrades. A single pane might pass basic rules. But when the fall height grows, building rules push you to multi-laminated setups. Many builders like them for step handrails because they fight strong hits. And they stay put even if cracked.

High Traffic Safety Barriers

In business places, laminated safety glass gets picked for lasting power. Picture shopping centers or airports, where lots of folks walk every day. Multi-laminated glass panels there give added shield without dropping clear view or style pull.

Acoustic and Energy Control

Sound mess is another thing. With sound blocking PVB middle layers, laminated units cut outer noise. This makes them a common pick in city jobs. Mix that with Low-E coats or colored glass. Then you balance safety with power saving.

Decorative and Specialty Applications

Multi-laminated doesn’t always mean boring. You can pick pretty versions, like rice paper laminated glass that mixes style with safety. Digital printing or silk screen frit patterns can get added during making. So, these panels turn into both support parts and eye catching bits.

Why One Layer Is Not Enough for Structural Needs

When a panel fills a small gap, a single laminated sheet may do fine. But once the plan asks for wide areas, big shapes, or heavier weights, you need more. Multi-laminated panels deal with hits better. They cut bending. And they stay whole even in rough spots.

Landson Glass makes structural toughened laminated glass. It joins heat treated power with laminated safety. This double plus makes it a favored choice for jobs that can’t give up between look charm and rule following.

Key Features of Multi-Laminated Glass Panels

Thickness Range: 9.52 mm to 33.04 mm, good for both home and business jobs.

Large Sizes: Up to 2700 x 4580 mm, giving room in plans.

Interlayer Variety: PVB (architectural and acoustic), SG®, Vanceva®, plus choices for sound or pretty EVA.

Glass Types: Clear, tinted, Low-E, acid etched, patterned, or rice paper infused.

Processing Options: Edgework, holes, cutouts, silkscreen frit, or digital print.

Packaging and Delivery: Timber end caps or crates fit to job needs, with usual wait times of 2–3 weeks ex-factory.

These details show why multi-laminated panels get seen as handy. They fit to support, sound, or pretty demands without hurting safety.

Landson Glass and Its Role in Multi-Laminated Solutions

Landson Glass has been giving to the glass field since 2002. It covers Australia, New Zealand, and European spots. The firm runs weather controlled laminating lines to get steady quality. It meets Australian, New Zealand, and European rules.

Beyond giving stock, Landson gives custom panels with many laminates, pretty ends, or sound work. The skill to mix exact making with plan bend is what makes their goods trusted in big jobs. You can look at their picture set to see real uses across home and business areas.

For exact job asks or prices, you can link through the contact page.

How Multi-Laminated Panels Perform in Real Life

In real use, you spot the change most in how panels act under push. A big balustrade panel from single laminate might break into sharp parts if struck hard. A multi-laminated one cracks but sticks together. Because the middle layers work like glue. In packed places, this change can mean skipping mishaps.

Another case is sound cut. In an office building near a busy street, laminated units with sound PVB drop noise amounts a bunch. Multi-laminated setups boost this effect. They make calmer insides without added wall parts.

Choosing the Right Option for Your Project

When you pick laminated glass, you should ask three questions. What weight and hit will the glass meet? Is sound or power work also key? How big and tricky is the panel plan?

If the answer to any leans to higher work, multi-laminated answers are worth thinking about. With Landson’s making skill, you can name custom middle layers, glass kinds, and patterns. This makes the glass both a support bit and a plan star.

FAQ

Q1: What makes multi-laminated glass different from standard laminated glass?

A: Standard laminated glass has two sheets with one interlayer, while multi-laminated uses several sheets and multiple interlayers for greater strength and safety.

Q2: Can multi-laminated glass panels reduce noise?

A: Yes, panels with acoustic interlayers like PVB can lower outside noise, and multi-laminated assemblies perform even better in busy urban environments.

Q3: How thick can multi-laminated panels be?

A: Thickness ranges from 9.52 mm up to 33.04 mm, depending on project needs.

Q4: What design options are available for multi-laminated panels?

A: Choices include clear, tinted, Low-E, acid etched, and decorative versions like rice paper laminated glass or printed patterns.

Q5: How fast can custom laminated panels be delivered?

A: Landson Glass typically offers 2–3 weeks ex-factory lead time, with tailored packaging to protect large panels during shipping.